By Andrew Tangel, Andy Pasztor and Alison Sider

Boeing Co. has found debris inside the fuel tanks of about

two-thirds of undelivered 737 MAX jets inspected so far, according

to federal and aviation-industry officials, indicating a bigger

production-related problem than the company previously

suggested.

The revelation comes as the plane maker struggles to restore

public and airline confidence in the grounded fleet.

A Boeing spokesman said Friday the plane maker has found debris

in fuel tanks of about 35 jets.

While Boeing disclosed the debris problem publicly earlier this

week, the latest details shed more light on the scale of the issue.

Industry officials said Boeing has so far inspected about 50 of

roughly 400 MAX planes awaiting delivery once regulators allow the

jet back in the air. Materials left behind include tools, rags and

boot coverings, according to industry officials familiar with the

details.

The problem marks the latest in a string of setbacks stretching

over many months that have delayed the return of the MAX to

commercial service while raising questions about the plane maker's

safety and engineering culture.

Boeing's initial comments on Tuesday indicated it came across

evidence of such assembly-line lapses in several MAX jets, without

disclosing the precise number or the total that had been inspected.

Boeing executives have recently pledged greater transparency

following a series of belated disclosures to regulators, airlines

and the public.

On Friday, the Boeing spokesman said inspections first found the

fuel-tank debris in late November and immediately notified the

Federal Aviation Administration. He said the manufacturer has added

safeguards to prevent workers from leaving materials inside fuel

tanks at its 737 factory in Renton, Wash., and beefed up efforts

across the company.

"Boeing is taking it very, very seriously," the spokesman

said.

The FAA earlier this week said that once Boeing informed it

about the problems, the agency moved to step up surveillance and

plans further action as appropriate based on additional inspection

findings. On Friday, an agency spokesman reiterated the voluntary

inspections are "part of the company's ongoing efforts to ensure

manufacturing quality."

Boeing has also broadened its debris inspections to cover other

interior spaces and compartments inside the MAX besides fuel tanks,

according to industry and government officials.

Industry officials cautioned that the percentage of planes with

problems may decline as inspections progress, depending on the time

period in which they were assembled and other factors.

The inspections have raised red flags, some of the officials

said, because Boeing's commercial-airplane unit traditionally has

been recognized as a leader in devising systems to combat such

production lapses. All tools used inside aircraft are supposed to

be logged and tagged, with employees double-checking each other to

verify each piece of equipment is removed. The Boeing spokesman

said the company has ramped up such checks to prevent future

problems.

Regulators have grounded the aircraft since March 2019,

following the second of two fatal crashes that killed a total of

346 people.

Boeing has assigned a team to look after the parked planes, many

of them already painted in the colors of the airlines buying them,

conducting regular checks to prepare for their eventual delivery

when regulators give the green light.

Unwanted tools and debris left inside finished airplanes can

pose various operational risks. In fuel tanks, such debris can clog

fuel lines and damage sensors, pumps or interior linings.

The emergence of so-called foreign object debris, known in the

industry as FOD, comes as Boeing and regulators have been grappling

with much more complicated technical issues for more than a year:

fixing a flight-control system implicated in both fatal crashes and

overhauling related pilot training.

Boeing has said it doesn't expect checking planes and removing

any debris to delay the MAX's clearance from regulators to return

to service, which it currently expects to start midyear. But the

new problem raises fresh questions about Boeing's ability to

resolve lingering lapses in quality-control practices and presents

another challenge to Chief Executive David Calhoun, who took charge

in January.

MAX operators and customers said they became aware of the issue

with the undelivered MAX jets earlier this week.

Some airlines said they were taking steps to ensure that there

wasn't any debris in planes that have already been delivered and

were operational before the grounding. Southwest Airlines Co. said

it had already been planning to inspect the fuel tanks of the 34

stored MAX planes it operated prior to the grounding before they

return to service. A spokesman for American Airlines Group Inc.

said the airline conducts its own inspections before and after

taking delivery of new planes. American said it would perform

additional inspections on its 24 grounded MAX jets before they

return to service, though there have been no signs of problems with

debris in those planes. United Airlines Holdings Inc. also said it

plans to inspect its MAX planes, including the fuel tanks, before

they resume flying.

In addition, FAA inspectors will check every MAX individually

for required maintenance, various inspections and suitable

readiness before allowing it to carry passengers.

The 737 MAX is the latest Boeing jet to face such problems. Last

year, debris was found on some 787 Dreamliners, which Boeing

produces in Everett, Wash., and North Charleston, S.C.

Boeing also twice had to halt deliveries of the KC-46A military

refueling tanker to the U.S. Air Force after tools and rags were

found in planes after they had been delivered from its Everett

factory north of Seattle.

Pentagon leaders said last March that it could take a year for

Boeing to rebuild trust in the program.

"It does not take a rocket scientist to deliver an airplane

without trash and debris on it," Air Force procurement chief Will

Roper said in an interview last June. "It just merely requires

following a set of processes, having a culture that values

integrity of safety above moving the line faster for profit. And

Boeing has certainly conveyed they're serious [about] restoring

that culture."

Later that year, in October, Boeing ousted its

commercial-airplane division chief, Kevin McAllister, as the MAX

crisis dragged on. In December, the company's board -- then headed

by Mr. Calhoun -- removed then-CEO Dennis Muilenburg and installed

Mr. Calhoun as his successor.

Boeing has said it had put in place new procedures to keep

debris out of finished airplanes. It halted MAX production in

January amid the prolonged grounding.

Boeing's general manager for the 737 program, Mark Jenks, in a

message to employees earlier this week, said: "FOD is absolutely

unacceptable."

With MAX production halted, Boeing's Renton, Wash., factory

still produces military versions of the 737 for the U.S. Navy and

some international customers, including the U.K.'s Royal Air

Force.

The Navy, which started receiving the P-8A Poseidon jets in

2012, hasn't found any debris in the aircraft's fuel tanks, a

spokeswoman said. Government inspectors have for years conducted

their own checks along with Boeing personnel, she added.

Doug Cameron contributed to this article.

Write to Andrew Tangel at Andrew.Tangel@wsj.com, Andy Pasztor at

andy.pasztor@wsj.com and Alison Sider at alison.sider@wsj.com

(END) Dow Jones Newswires

February 21, 2020 22:18 ET (03:18 GMT)

Copyright (c) 2020 Dow Jones & Company, Inc.

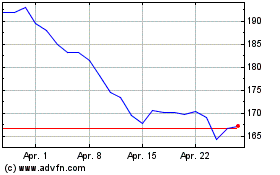

Boeing (NYSE:BA)

Historical Stock Chart

Von Mär 2024 bis Apr 2024

Boeing (NYSE:BA)

Historical Stock Chart

Von Apr 2023 bis Apr 2024