Form SD - Specialized disclosure report

24 Mai 2024 - 10:01PM

Edgar (US Regulatory)

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM SD

Specialized Disclosure Report

RPC, INC.

(Exact name of registrant as specified in its charter)

| | |

Delaware | 1-8726 | 58-1550825 |

(State or other jurisdiction

of incorporation) | (Commission File Number) | (IRS Employer Identification No.) |

2801 Buford Highway NE, Suite 300, Atlanta, Georgia 30329 |

(Full mailing address of principal executive offices) |

| |

Michael L. Schmit | (404) 321-2140 |

(Name and telephone number, including area code, of the person in connection with this report.) |

Check the appropriate box to indicate the rule pursuant to which the form is being filed, and provide the period to which this form is being filed:

☒ | Rule 13p-1 under the Securities Exchange Act (17CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023. |

☐ | Rule 13q-1 under the Securities Exchange Act (17CFR 240.13q-1) for the reporting period from January 1 to December 31, 2023. |

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

This Specialized Disclosure Form (Form SD) of RPC, Inc. and its subsidiaries (“RPC” or “the Company”) is filed pursuant to Rule 13p-1 (“the Rule”) of the Securities Exchange Act of 1934, as amended. The Rule requires disclosure of certain information when a company manufactures or contracts to manufacture products where the minerals specified in the Rule are necessary to the functionality or production of those products. Additional information is required where the Company has reason to believe that the minerals originated in the Democratic Republic of the Congo (“DRC”) and certain adjoining countries (collectively, the “Covered Countries”). The specified minerals are gold, columbite-tantalite (coltan), cassiterite, and wolframite, including their derivatives, which are limited to tantalum, tin and tungsten (collectively, the “Conflict Minerals”).

In accordance with the Rule, the Company evaluated its products and determined that during calendar year 2023 certain products it manufactured or contracted to manufacture contained tungsten. As required by the Rule, the Company conducted a good faith reasonable country of origin inquiry regarding the Conflict Minerals by doing a survey of the suppliers of products that contained Conflict Minerals, using the Electronic Industry Citizenship Coalition and Global e-Sustainability Initiative Conflict Minerals Reporting Template (“EICC/GeSI Template”). The EICC/GeSI Template is designed to confirm the use of Conflict Minerals in the covered products, to identify the source of the Conflict Minerals, and to determine whether any of the Conflict Minerals originated in the Covered Countries, or from recycled, or scrap sources.

Conflict Minerals Disclosure

The Company’s Conflict Minerals Report is filed as an exhibit herewith and is available on the Company’s website at www.rpc.net under the Governance section.

Item 1.02 Exhibit

Conflict Minerals Report required by Item 1.01 is filed as an exhibit to this Form SD.

Section 3 – Exhibits

Item 3.01 Exhibits

Exhibit 1.01 – Conflict Minerals Report as required by Items 1.01 and 1.02 of this Form.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

| | |

RPC, Inc. | | |

(Registrant) | | |

| | |

| | |

/s/ Michael L. Schmit | | May 24, 2024 |

Michael L. Schmit Vice President, Chief Financial Officer, Treasurer and Corporate Secretary | | (Date) |

Exhibit 1.01

CONFLICT MINERALS REPORT

This report has not been subject to an independent private sector audit.

RPC, Inc. (“RPC” or “the Company”) provides a broad range of specialized oilfield services and equipment primarily to independent and major oil and gas companies engaged in the exploration, production and development of oil and gas properties.

(2) | Conflict minerals and Covered Countries |

“Conflict Minerals” or “3TG” are gold, columbite-tantalite (coltan), cassiterite, wolframite or their derivatives, which are limited to tantalum, tin, and tungsten. “Covered Countries” are the Democratic Republic of the Congo (DRC) and certain adjoining countries.

(3) | Reasonable Country of Origin Inquiry (“RCOI”) and Nationally or internationally recognized due diligence framework |

RPC does not purchase raw ore or unrefined Conflict Minerals directly from mines, smelters or refiners and makes no direct purchases of any minerals in the Covered Countries. The Company’s supply chain with respect to the products that use Conflict Minerals is complex, with intermediaries and third parties in the supply chain between the manufacture of products and the original sources of Conflict Minerals. The Company must therefore rely on its suppliers to provide information on the origin of the 3TG contained in components and materials supplied, including sources of 3TG that are supplied to them from their suppliers (i.e., second-tier suppliers). The Company surveyed 100 percent of its direct suppliers of raw materials and components. This risk-based approach is consistent in all material aspects with the framework in the Organization for Economic Co-operation and Development (“OECD”) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and the related Supplements on gold and tin, tantalum and tungsten.

The Company conducted the following due diligence measures:

| · | Identified those products which it manufactured or contracted to manufacture that contained one or more of the Conflict Minerals or its derivatives and determined that four of the products it sells contain tungsten. |

| · | RPC conducted a survey of the direct suppliers that were identified as supplying products that contain Conflict Minerals. We used the Conflict Minerals Reporting Template (“CMRT”) published by the Electronic Industry Citizenship Coalition and Global e-Sustainability Initiative (“EICC/GeSI”) Conflict Free Sourcing Initiative (“CFSI”). CMRT maintains a list of smelters that have received a conflict free designation from the CFSI. All smelter information provided by the vendors was compared against the list maintained by CMRT. |

(5) | Results of Due Diligence |

The Company received responses from 100 percent of the suppliers surveyed and the results are as follows:

| · | 67 percent confirmed that 3TG used in their products is not from the Covered Countries and identified smelters that were on the CFSI list. |

| · | Eight percent confirmed that 3TG used in their products are from recycled or scrap sources. |

| · | 17 percent confirmed that 3TG used in their products is not from the Covered Countries but did not provide a list of the smelters from which the minerals are sourced or listed smelters that were not on the CFSI list. |

| · | Eight percent confirmed that 3TG was used in their products, but they did not know where the minerals were sourced from. |

Some of the challenges that we encountered when we obtained the responses were as follows:

| · | We depend on information received from our direct suppliers to conduct our good faith RCOI process. |

| · | We have a varied supplier base with differing levels of resources and sophistication, and many of the suppliers are not subject to Rule 13p-1 of the Exchange Act. |

| · | Certain suppliers were unable or unwilling to specify the smelters or refiners used for components and materials supplied to us. |

(6) | Steps to be taken to mitigate risk |

| · | We will continue to improve our due diligence measures and clearly communicate expectations to our direct suppliers concerning transparency and sourcing of materials and components containing Conflict Minerals. |

| · | The Company will continue to use CMRT as part of the supplier inquiry process for 2024. |

The products that the Company contracts to have manufactured which contain Conflict Minerals are described below:

Product

Description | Processing Facility | Country of

Origin | Efforts to

Determine

Origin |

Mills used to grind or cut and remove metal, composites or other materials in downhole oilfield completion and workover activities Motors used to perform services or convey tools in downhole oilfield completion activities Tools used to create perforations in well casing to prepare a well for hydraulic fracturing operations Hydraulically actuated rotary impact tools which move casing sleeves and clean out debris during oilfield completion operations | A partial list of the facilities used in these products that are contracted to be manufactured and have a “conflict free” designation on the CFSI list is shown below: ● Asia Tungsten Products Vietnam Ltd. ● ATI Metalworking Products ● Changsha South Tantalum Niobium Co. Ltd. ● Chenzhou Diamond Tungsten Products Co. Ltd. ● Chenzhou Yunxiang Mining and Metallurgy Co. Ltd. ● Chiefeng Dajingzi Tin Industry Co. Ltd. ● China Molybdenum Tungsten Co. Ltd. ● Chongyi Zhangyuan Tungsten Co. Ltd. ● Dongguan CIEXPO Environmental Engineering Co. Ltd. ● Estanho de Rondonia S.A. ● FIR Metals & Resource Ltd. ● Fujian Xinlu Tungsten co. Ltd. ● F&X Electro- Materials Ltd. ● Ganzhou Haichuang Tungsten Co., Ltd. ● Ganzhou Huaxing Tungsten Products Co. Ltd. ● Ganzhou Seadragon W & Mo Co Ltd. ● Global Advanced Metals Boyertown ● Global Advanced Metals Aizu ● Global Tungsten & Powders Corp. | Based on the Company’s due diligence efforts to date, the list of countries of origin for the relevant products is shown below: | The efforts to determine the origin of conflict minerals are discussed above |

| ● Guangdong Xianglu Tungsten Co. Ltd. ● Guangdong Zhiyuan New Material Co. Ltd. ● Ganzhou Haichuang Tungsten Co. Ltd. ● Ganzhou Jiangwu Ferrotungsten co. Ltd. ● H.C. Starck Tungsten GmbH ● H.C. Starck Hermsdorf GmbH ● H.C. Starck Tungsten GmbH ● H.C. Starck Tantalum and Niobium GmbH ● Hengyang King Xing Lefeng new Materials Co. Ltd. ● HuiChang Hill Tin Industry Co. Ltd. ● Hunan Chenzhou Mining Co., Ltd. ● Jiangwu H.C. starck Tungsten Products Co. Ltd. ● Jiangxi Dinghal Tantalum & Nobium Co. Ltd. ● Jiangxi Gan Bei Tungsten Co. Ltd. ● Jiangxi New Nanshan Technology Ltd. ● Jiangxi Tonggu Non-ferrous Metallurgical &Chemical Co. Ltd. ● Jiangxi Tuohong New Raw Material ● Jiangxi Xinsheng Tungsten Industry Co. Ltd. ● JiangXi Yaosheng Tungsten Co. Ltd. ● JiuJiang JinXin Nonferrous Metals Co., Ltd. ● Malaysia Smelting Corporation (MSC) ● Malipo Haiyu Tungsten Co. Ltd. ● Masan Tungsten Chemical LLC (MTC) ● Metallurgical Products India Pvt. Ltd. ● Mettallic Resources, Inc. ● Mitsui Mining & Smelting Co., Ltd. ● Ningxia Orient Tantalum Industry Co. Ltd. ● Nui Phao H.C. Starck Tungsten Chemicals ● Phillippine Chuangxin Industrial Co., Inc. ● Pongpipat Company Limited ● Precious Minerals and Smelting Limited ● Resind Industria e Comercio Ltda. ● Solikamsk Magnesium Works OAO ● Ulba Metallurgical Plan JSC ● Unecha Refractory metals plant ● Wolfram Bergbau und Hutten AG ● Xiamen Tungsten (H.C.) Co., Ltd | | |

| Precious Minerals and Smelting Limited RFH Tantalum Smeltry Co. Ltd. Resind Industria e Comercio Ltda. Rui Da hungSolikamsk Magnesium Works OAO South-East Nonferrous Metal Company limited of Hengyang City Tejing (Vietnam) Tungsten Co. Ltd. Ulba Metallurgical Plan JSC Unecha Refractory metals plant Vietnam Youngsun Tungsten Industry Co. Ltd Wolfram Bergbau und Hutten AG Tejing (Vietnam) Tungsten Co. Ltd. Xinhai Rendan Shaoguan Tungsten Co. Ltd. XnXing HaoRong Electronic Material Co. Ltd. | | |

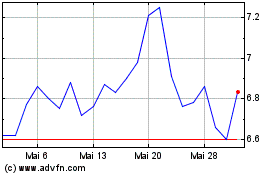

RPC (NYSE:RES)

Historical Stock Chart

Von Nov 2024 bis Dez 2024

RPC (NYSE:RES)

Historical Stock Chart

Von Dez 2023 bis Dez 2024