Applied Materials Breakthrough To Bring OLED Displays to Tablets, PCs and TVs

21 November 2024 - 1:30PM

Applied Materials, Inc. today introduced the MAX OLED™ solution, a

patented OLED pixel architecture and revolutionary display

manufacturing technology designed to bring the superior OLED

displays found in high-end smartphones to tablets, PCs and

eventually TVs.

OLED is the display technology of choice for the world’s leading

smartphone manufacturers because it offers superior display

quality, light and flexible form factors, and durability. However,

until today, it has proven challenging to scale OLED display

manufacturing to the larger glass panels used to make displays for

tablets, PCs and TVs.

Applied’s MAX OLED solution makes it easier to scale OLED

manufacturing from Gen 6* glass substrates to Gen 8* substrates,

which are approximately two times larger, and beyond. In addition,

the MAX OLED solution deposits OLED materials in a new way that

increases pixel brightness and resolution, reduces display energy

consumption, and lengthens display lifetime.

The MAX OLED solution has strong customer interest, with repeat

orders from multiple leading display manufacturers. Additionally,

Applied will supply a MAX OLED solution to Samsung Display, a

leading global manufacturer of OLED and QD-OLED panels. Samsung

Display will be bringing in an alpha system to assess this new

technology.

“The consumer electronics industry has been waiting for a

breakthrough that can bring OLED technology to the hundreds of

millions of tablets, PCs and TVs sold each year,” said Dr. Brian

Shieh, Group Vice President and General Manager of Applied’s

Display and Flexible Technology business. “We are proud to be

partnering with Samsung Display to help bring this revolutionary

technology to the global marketplace.”

Making OLED Displays Brighter, Longer-Lasting and More

Energy-Efficient

OLED displays are difficult to manufacture because the materials

used to emit red, green and blue are fragile and ruined by any

exposure to air or moisture. Applied’s MAX OLED solution is a

breakthrough technology that deposits and encapsulates each pixel

individually using a specially designed maskless process. Applied’s

approach is precise, fast and superior at maintaining the purity of

delicate OLED materials.

Applied’s proprietary solution uses selective deposition to

enable excellent pixel placement accuracy, more than doubling the

amount of OLED material per area as compared to previous

technologies. The technology can increase OLED display brightness

by as much as 3X and increase resolution by as much as 2.5X, to

approximately 2,000 pixels per square inch. The solution can also

reduce display power consumption by more than 30 percent and

increase display lifetime by up to 5X.

“Applied Materials has developed a true breakthrough in OLED

manufacturing technology that will enable better OLED displays at

more attractive prices,” said Ross Young, Co-founder and CEO of

Display Supply Chain Consultants (DSCC). “This technology has the

potential to accelerate OLED adoption in a range of markets, from

tablets and PCs to automobiles and micro-displays for AR/VR,

creating a catalyst for the entire display industry.”

New OLED Pixel Architecture, Process Recipe and

Integrated Materials Solution

The MAX OLED solution is more than equipment: it begins with a

proprietary pixel architecture built using a patented manufacturing

recipe that results in best-in-class OLED pixels and displays. The

manufacturing system combines a number of critical manufacturing

modules in a single, high-vacuum system that protects the delicate

OLED materials from the environment and reduces yield-killing

particles. The MAX OLED system integrates display glass handling,

multiple OLED deposition steps, and OLED encapsulation. Many of the

core technologies used by the MAX OLED solution have already been

proven by Applied in making large-area LCD screens at panel sizes

up to Gen 10.5*.

The MAX OLED solution reduces the energy consumption of OLED

display fabs, requires significantly less OLED materials, and

eliminates the need for mask cleaning chemicals, thereby reducing

the environmental impact of display manufacturing.

A Growing OLED Display Opportunity

Applied is already the world’s largest provider of display

manufacturing equipment, with a broad portfolio of products

spanning CVD** and PVD** deposition, CVD thin-film encapsulation,

and eBeam testing and inspection. The MAX OLED solution is expected

to more than double Applied’s served addressable market opportunity

in OLED display manufacturing.

*Gen 6 glass panel surface area = 2.78 square meters; Gen 8

surface area = 5.5 square meters; Gen 10 surface area = 9.9 square

meters**PVD = physical vapor deposition; CVD = chemical vapor

deposition

Forward-Looking StatementsThis press release

contains forward-looking statements, including those regarding

anticipated benefits of our new products and technologies, expected

growth and trends in our businesses and markets, industry outlooks

and demand drivers, technology transitions, and other statements

that are not historical facts. These statements and their

underlying assumptions are subject to risks and uncertainties and

are not guarantees of future performance. Factors that could cause

actual results to differ materially from those expressed or implied

by such statements include, without limitation: failure to realize

anticipated benefits of our new products and technologies; the

level of demand for semiconductors and for our products and

technologies; customers’ technology and capacity requirements; the

introduction of new and innovative technologies, and the timing of

technology transitions; market acceptance of existing and newly

developed products; the ability to obtain and protect intellectual

property rights in technologies; our ability to ensure compliance

with applicable law, rules and regulations; and other risks and

uncertainties described in our SEC filings, including our recent

Forms 10-Q and 8-K. All forward-looking statements are based on

management’s current estimates, projections and assumptions, and we

assume no obligation to update them.

About Applied MaterialsApplied Materials, Inc.

(Nasdaq: AMAT) is the leader in materials engineering solutions

used to produce virtually every new chip and advanced display in

the world. Our expertise in modifying materials at atomic levels

and on an industrial scale enables customers to transform

possibilities into reality. At Applied Materials, our innovations

make possible a better future. Learn more at

www.appliedmaterials.com.

Applied Materials Contact:Ricky Gradwohl

(editorial/media) 408.235.4676Liz Morali (financial community)

408.986.7977

A photo accompanying this announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/8d0fc91b-33c4-41c3-9dca-3dcea6e988e2

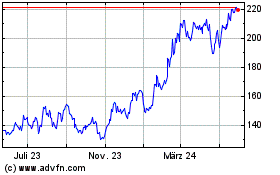

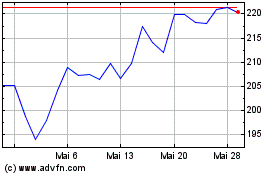

Applied Materials (NASDAQ:AMAT)

Historical Stock Chart

Von Dez 2024 bis Jan 2025

Applied Materials (NASDAQ:AMAT)

Historical Stock Chart

Von Jan 2024 bis Jan 2025