Gold Bull Resources Corp. (TSX-V: GBRC) (“

Gold

Bull” or the “

Company”) is pleased to

report its initial Abel Knoll Bottle Roll Leach Test work conducted

in September 2021 at its 100% owned Sandman Project

(“

Sandman” or the “

Project”)

located in Humboldt County, Nevada, USA.

HIGHLIGHTS & UPDATE:

- Abel

Knoll Bottle Roll Leach Test work returned an average of 88%

extracted (recovered) gold from oxide material with a maximum of

97% extracted gold

- Results

are consistent with prior historical tests completed by Newmont at

Silica Ridge and South East Pediment and Kennecott’s test work at

North Hill, Silica Ridge and Southeast Pediment

- These

are preliminary tests and further optimisation work is planned for

mine studies

- Upside

in extracted silver value identified and not included in current

resource estimate

- Oxide

ore extends down to 201m at Abel Knoll which is very encouraging

for gold oxide recovery

- 2021

drill holes at Abel Knoll included:

- SA-0001

intersected 144.8m (475 ft) at 1.58g/t Au from 65.5m (215 ft) which

included 97.5m at 2.06g/t Au from 96m and 6.1m @ 7.77g/t Au from

143.3m

- SA-0031

intersected 90 m (295 ft) at 0.6 g/t Au from 76.2 m (outside the

current resource)

-

Southeast Pediment yielded 92.5% extracted gold with

gravity concentration and 85.8% extracted gold without gravity

concentration (historically)

Gold Bull CEO, Cherie Leeden commented:

An average of

88% gold recovering from Abel Knoll without doing any metallurgical

optimization work is exceptional. We focussed our study on Abel

Knoll because there had not been previous metallurgical work done

on that deposit yet we had some impressive drill hits at Abel Knoll

this year. These excellent metallurgical gold recoveries are very

similar to the historical metallurgical recovery data we inherited

for our other three deposits (North Hill, Silica Ridge and

South-East Pediment). Additional optimization metallurgical work is

planned for next year, that will feed into a feasibility

study.

Background

Bottle Roll Leach Test work results

Gold Bull submitted 24 samples to Kappes,

Cassiday & Associates (KCA) metallurgy laboratory in Reno,

Nevada in September 2021 to provide preliminary test work of gold

recovery for the Abel Knoll deposit as no prior metallurgical work

had been completed at this ore deposit. The oxide sample results

are very encouraging with an average of 88% gold extracted and

maximum recovery 97% from the oxide sample material. These are

preliminary test work results, and no optimisation work has been

completed.

The gold recovery results are similar to

Newmont’s prior test work completed at Southeast Pediment and

Silica Ridge and Kennecott’s prior work at North Hill, Silica Ridge

and Southeast Pediment.

The 24 samples were sourced from the Abel Knoll

ore deposit and comprised composite reverse circulation samples

sourced from a range of deposit depths, lithology and oxidation

states. A wide range of mineralised samples were submitted to test

the variation of the deposit results in oxide, transitional and

sulfide ore horizons over varying depths. The sample material was

utilized exclusively for Bottle Roll Leach Test work. The analysis

including preparation, assaying and metallurgical studies utilizing

accepted standard industry procedures and a specialist experienced

metallurgical laboratory KCA.

The maximum percentage gold extracted was 97%

gold with an average of 73% over all of the oxide, transitional and

sulfide ore horizons. The results reflect with the presence of

sulphide in sample materials which reduces leach recovery where the

oxide and oxide transitional samples returned encouraging results

>80% gold extracted and those from fresh rock with sulfide

returned lower results as anticipated from this type of leach test

work.

Figure 1. Map showing location of the mineral resources at

Sandman.

Gold extraction for the nine oxide

samples averaged 88% and ranged from 80% to 97% extracted

gold. Gold extraction for the six samples listed as

sulfide material averaged 64% with maximum 91%. Gold extraction for

the nine samples comprising transitional oxide-sulfide material

averaged 65%. These results collectively show a general trend

transitioning from oxide to deeper fresh sample material which is

considered normal for bottle roll leach test work. All three holes

tested show a gradual decrease in leach gold extraction with depth

as the material transitions from oxide to deeper sulfide ore. Oxide

ore extends from surface to a depth of 201m (660 feet) in the

western Abel Knoll diatreme breccia and ranges from 53m (175 feet)

to 80m (265 feet) depth from surface in the eastern portion of the

deposit.

A summary of GBRC’s bottle roll leach test work results are

summarised in the table below.

Sandman Project - Abel

KnollSummary of Cyanide Bottle Roll Leach Tests -

Gold

Table 1 Abel Knoll preliminary test work results from

cyanide bottle roll leach test work with gold extracted in

percentage reported by KCA laboratory

The Abel Knoll deposit has low levels of silver and Gold Bull’s

Bottle Roll Leach Test work returned an average of 24% extracted

silver with maximum 63%. Those samples with higher silver

extractions were sourced from the higher grade non oxide materials.

These test results are indicative only and have not been

optimised.

Sandman Project - Abel Knoll Ore

DepositSummary of Cyanide Bottle Roll Leach Tests

- Silver

Table 2 Abel Knoll preliminary test work results from

cyanide bottle roll leach tests with gold extracted in percentage

reported by KCA laboratory

The graph below shows the extracted gold within

oxide material returning consistently higher gold recoveries

(orange) compared to transitional material (light grey) and sulfide

material (dark grey). The two samples returning >80% extracted

gold from the sulfide material are likely to form part of the

transitional material given this is a preliminary test to determine

the range of leach recoveries for the Abel Knoll deposit.

Sandman Project - Abel Knoll Ore

DepositGold Extraction v’s oxide to fresh

ore

Graph 1. Graph depicting extracted gold in

percentage per material type. Samples are colour coded with

orange showing oxide extracted gold, light grey being transitional,

and dark gray sulfide extracted gold.

The graph below shows the extracted gold over

the depth of intermittent composite samples from surface in hole

SA-001 and indicates the general tapering of extracted gold with

depth from 70 to 210m (240 to 680 feet). The oxide boundary of the

diatreme breccia in the west of the ore deposit is deep at 201m

(660 feet) from surface and the eastern stratigraphic oxide

boundary ranges from 53m (175 feet) to 80m (265 feet) depth from

surface. The extracted gold oxide material test work results are

very encouraging given the depth of the diatreme breccia at 201m

(660 feet) is deep.

Graph 2. Graph depicting extracted gold in hole

SA-0001 with depth in feet, there is a gradational trend of

reducing extracted gold where the oxide and transitional materials

return higher leach recovery compared to the deeper sulphide

ore.

Bottle Roll Leach Test Work Process

The objective of the Bottle Roll Leach Test work

was to test the variability of gold recovery on a range of ores,

including variability of gold recovery from oxide to sulfide ores

sourced from different depths of the Abel Knoll deposit. No prior

test work has been conducted from the Abel Knoll deposit.

- A range of

composite sample intervals were selected to test variation of gold

recovery and other parameters including oxidation state driven by

geology factors and depth from surface, geological variation with

regards to host rocks including Tertiary Diatreme, Tertiary and

Basement rocks as well as alteration and the presence of sulfides

in fresh rock. A range of variable oxide materials were selected

with samples sourced from oxide, transitional and

transitional/sulfide ore horizons. Hole SA-0001 is included in the

Abel Knoll Mineral Resource Estimate (MRE) while SA-0031 and

SA-0033 are new holes and are not included in the existing Abel

Knoll MRE and are resource extensions of the Abel Knoll MRE.

- Samples for the

bottle roll test work were sourced from composite reverse

circulation samples taken during Gold Bull’s 2021 exploration

drilling program and were initially analysed for gold and

multi-element geochemistry at American Assay Laboratory (AAL) in

Reno, Nevada. The samples were jaw and roll crushed by AAL to 10

mesh (2mm) and composited per down hole interval with 24 samples

submitted to KCA laboratory.

- Each sample

received at KCA was weighed, blended and split using a Jones Riffle

splitter to create a 500-gram portion of the composite sample to be

utilised for the Bottle Roll Leach Test work.

- Bottle Roll

Leach Test work was completed on the as-received composite samples

at KCA with the addition of Leachwell. Leachwell was used as a

catalyst to increase the kinetics of the leach. The Leachwell

product used does not contain cyanide.

- KCA tail assays

for gold were ran as one assay ton (1AT) or 30-gram fire assay by

standard fire assay methods with gravimetric or flame atomic

absorption spectrophotometric (FAAS) finish. Tail assays for silver

were ran as one assay ton (1AT) or 30-gram fire assay by standard

fire assay method with gravimetric finish or through a four acid

digestion of a 0.25 to 0.50 gram sample with FAAS finish.

- The Bottle Roll Leach Test work

procedure comprised the following.

- One 500 gram

split of as received material was placed into a 3.5-liter bottle

and slurried with additional tap water to a total of 750

milliliters of added water.

- The slurry was

mixed thoroughly, and the pH of the slurry checked. The pH of the

slurry was adjusted, as required, to greater than 10.5 with

hydrated lime.

- Sodium cyanide

was added to the slurry to a target amount of 2.0 grams per litre

sodium cyanide. Leachwell was added to the slurry to a target

amount of 20 grams per litre Leachwell. The bottle was then placed

onto a set of laboratory rolls. Rolling throughout the duration of

the test mixed the slurry (15 rpm).

- After 24 hours

of continuous rolling, the slurry was checked for pH, dissolved

oxygen (DO), NaCN, Au, Ag and Cu.

- The slurry was

then filtered, washed, and dried.

- From the dry

tailings, duplicate portions were split out and individually ring

and puck pulverized to 80% passing 0.075 millimetres. The

pulverised portions were then assayed for residual gold and silver

content.

- The test work

was conducted with reagent grade hydrated lime for pH control. The

Parameters of the Bottle Roll Tests are summarised in the table

below.

Sandman Project - Abel

KnollParameters of Bottle Roll Tests by

KCA

Table 3. Parameters of Bottle Rolle tests

completed by KCA for Gold Bull in September 2021

Summary of Sample Materials

Samples received by KCA for the cyanide Bottle

Roll Leach Test work were sourced from Abel Knoll reverse

circulation drilling chips from holes SA-0001, SA0031 and SA-0033.

The table below provides a summary of materials selected for the

test work. The average sample weight was 1,200 grams with minimum

1,119 grams and maximum 1,283 grams. Some variation of gold grades

reported by AAL and KCA are evident of the coarse gold nugget

effect at Abel Knoll which has previously been studied at

Sandman.

Sandman Project - Abel Knoll Ore

DepositSummary of Received Samples at

KCA

Table 4. Summary of samples submitted to KCA for Bottle Roll

Test work including geology, rock type, redox, % sulfide,

alteration and AAL grade in which samples were selected. Note: The

Composite ID nomenclature includes drill hole prefix SA-0001,

SA0031 and SA0033 as well as the down hole foot depth of the

reverse circulation composite sample depth e.g. 220-240 foot in the

first line is the down hole composite sample depth.

HISTORICAL METALLURGICAL TEST RESULT SUMMARY: FOR

SOUTHEAST PEDIMENT, SILICA RIDGE AND NORTH HILL

This section discusses the historical Bottle Roll Testwork at

the Sandman deposit, all of the testwork was preliminary and has

not been optimised. Most of the samples were taken from reverse

circulation drill chips and drill core and early work from

trenches.

The draft below provides the location of testwork relative to

Sandman Mineral Resource Estimate (MRE) boundaries.

Figure 2. Map showing location of Abel Knoll Bottle Roll Leach

testwork locations as well as the locations for all historical

sample materials from Southeast Pediment, Silica Ridge and North

Hill relative to Sandman’s MRE.

North Hill and Silica Ridge – Newmont’s Historical Test

Results

Newmont conducted Bottle Roll Leach Test work at

Southeast Pediment and Silica Ridge. Their preliminary test work

was not optimised and concluded the following:

- Southeast

Pediment and Silica Ridge ore deposits contain material which can

be classified as free milling ores.

- Results at

Southeast Pediment yielded 92.5% extracted gold with gravity

concentration using material 80% passing 200 mesh grind (0.075mm)

and 85.8% extracted gold without gravity concentration. The Carbon

in Leach (CIL) did not significantly improve the test results nor

the additional of elevated cyanide. Their recoveries increased with

increasing head grade.

- Results at

Silica Ridge which included low grade samples yielded 85.1%

extracted gold with gravity concentration using material 80%

passing 200 mesh grind (0.075mm) and 80.4% extracted gold without

gravity concentration. Gold recovery averaged 89.9% extracted gold

without gravity concentration for material which graded between

0.03-0.2 ounce per tonne gold and 94.8% extracted gold for material

which graded above 0.2 ounce per tonne gold suggesting the higher

the gold grade the better the recovery.

Southeast Pediment - Newmont’s Historical Test

Results

Newmont’s test work material comprised 80%

passing -200 mesh (0.074mm) with 24 hour leach returning an average

of 85.75% extracted gold. Selected materials comprised majority

oxide as well as transitional and sulfide ore to test the

variability of results from the deposit, maximum recovery was 97%

and minimum 75.79% demonstrating relatively consistent results over

a range of variable oxidation materials. No flow sheet optimisation

test work was conducted and these were preliminary tests from

diamond core samples. Addition of the gravity concentration step

improved recovery for samples >90% extracted gold. Results for

Newmont’s Southeast Pediment Ore deposit preliminary variability

test work are provided in the table below.

Newmont’s Historical Test

ResultsSoutheast

Pediment -

initial bottle

roll results24 hr Leach, 80%

passing 200 mesh

|

Hole# |

Intervals |

Ore Type |

Sample ID |

Avg. Au opt |

80% Grind/Leach |

NaCN, lb/t |

Lime, lb/t* |

|

NSM-00004 |

66.3-74.9 |

Oxide |

Comp 1 |

0.077 |

79.81 |

1.94 |

1.2 |

|

NSM-00004 |

80.2-89.0 |

Oxide |

Comp2 |

0.064 |

79 |

1.96 |

1.4 |

|

NSM-00004 |

104.4-114.5 |

Oxide |

Comp3 |

0.047 |

82.98 |

1.94 |

1.31 |

|

NSM-00004 |

124.0-129.5 |

Oxide |

Comp4 |

0.266 |

78.99 |

1.94 |

1.33 |

|

NSM-00007 |

113.6-118.3 |

Oxide |

Comp5 |

0.38 |

75.79 |

1.94 |

1.34 |

|

NSM-00010 |

97.1-102.5 |

Trans |

Comp6 |

0.054 |

85.18 |

1.95 |

1.46 |

|

NSM-00010 |

79.0-82.7 |

Oxide |

Comp7 |

0.085 |

88.29 |

1.94 |

1.38 |

|

NSM-00010 |

114.5-117.6 |

Oxide |

Comp8 |

0.123 |

86.16 |

1.95 |

1.09 |

|

NSM-00010 |

127.6-129.2 |

Oxide |

Comp9 |

0.137 |

88.66 |

1.94 |

0.97 |

|

NSM-00010 |

138.2-141.0 |

Oxide |

Comp 10 |

0.183 |

83.1 |

1.94 |

1.29 |

|

NSM-00010 |

512.4-519.9 |

Sulf 1% |

Comp 11 |

0.043 |

82.87 |

2.94 |

1.66 |

|

NSM-00009 |

89.0-93.3 |

Oxide |

Comp 12 |

0.179 |

89.4 |

1.96 |

1.29 |

|

NSM-00009 |

110.0-112.0 |

Oxide |

Comp 13 |

0.505 |

94.75 |

1.94 |

1.25 |

|

NSM-00009 |

123.0-128.2 |

Sulf 2% |

Comp 14 |

0.071 |

79.51 |

2.97 |

0.68 |

|

NSM-00024 |

113.2-127.4 |

Ox Leach |

Comp 15 |

0.037 |

85.22 |

1.94 |

1.5 |

|

NSM-00024 |

160.0-165.0 |

Oxide |

Comp 16 |

0.048 |

88.42 |

1.96 |

2.29 |

|

NSM-00031 |

82.5-102.9 |

Ox Leach |

Comp 17 |

0.062 |

93.51 |

1.96 |

2 |

|

NSM-00019 |

69.8-74.0 |

Oxide |

Comp18 |

0.03 |

74.74 |

1.94 |

1.55 |

|

NSM-00019 |

76.6-79.7 |

Oxide |

Comp19 |

0.738 |

95.94 |

1.95 |

1.5 |

|

|

154.3-164.0 |

|

|

|

|

|

|

|

NSM-00017 |

171.1-177.1 |

Oxide |

Dup #1 |

0.263 |

95.59 |

1.47 |

2.62 |

|

|

154.3-164.0 |

|

|

|

|

|

|

|

NSM-00017 |

171.1-177.1 |

Oxide |

Dup#2 |

0.251 |

94.67 |

1.65 |

2.5 |

|

NSM-00017 |

177.1-193.5 |

Ox Leach |

Col#1 |

0.011 |

71.98 |

1.05 |

1.08 |

|

NSM-00033, |

48.9-95.4, |

|

|

|

|

|

|

|

NSM-00015 |

179.9-205.5 |

Ox Leach |

Col#2 |

0.028 |

94.37 |

0.88 |

1.82 |

|

NSM-00017 |

69-85.4 |

Oxide |

Col#3 |

0.076 |

96.92 |

1.58 |

3.04 |

|

NSM-00026, |

203.3-224.5 |

|

|

|

|

|

|

|

NSM-00033, |

95.4-125.3 |

|

|

|

|

|

|

|

NSN-00015 |

149.0-179.9 |

Ox Leach |

Col#4 |

0.013 |

76.78 |

1.35 |

2.27 |

|

NSM-00033, |

48.9-95.4 |

|

|

|

|

|

|

|

NSM-00015, |

179.9-205.5 |

|

|

|

|

|

|

|

NSM-00026, |

203.3-224.5 |

|

|

|

|

|

|

|

NSM-00033, |

95.4-125.3 |

|

|

|

|

|

|

|

NSN-00015 |

149.0-179.9 |

Ox Leach |

Col#5 |

0.019 |

86.81 |

0.93 |

2 |

|

Average |

85.75 |

1.84 |

1.61 |

| * Caustic

soda actual pH modifier, value is time equivalent |

Table 5. Summary of Newmont’s Southeast Pediment preliminary

Bottle Roll Leach Test work sourced from Newmont’s historical

files.

Cyanide and Lime consumptions were 1.84 lb/st

and 1.61 lb/st, respectively.

Summary of Newmont’s variability test work for

the Southeast Pediment Bottle Roll Test work is summarised below.

The results indicate gravity concentration improved the extracted

of gold from 85.9% to 92.53% and that Carbon in Leach (CIL) and

additional cyanide did not yield significantly improve results.

Newmont’s Historical Test

Results

Southeast

Pediment -

initial bottle

roll results

|

Sample ID |

1.5 inch BR Leach* |

80% Grind/Leach |

80% Grind/Grav/Leach |

80% Grind/CIL Leach |

80% Grind/Grav/CIL Leach |

80% Grind/Leach @ high CN |

|

Comp1 |

81.69 |

79.81 |

96.77 |

|

|

|

|

Comp2 |

82.2 |

79 |

94.64 |

|

|

|

|

Comp3 |

92.03 |

82.98 |

97.38 |

|

|

|

|

Comp4 |

83.85 |

78.99 |

76.1 |

|

|

|

|

Comp5 |

69.69 |

75.79 |

96.7 |

|

|

|

|

Comp6 |

69.22 |

85.18 |

93.08 |

|

|

|

|

Comp7 |

82.76 |

88.29 |

79 |

|

|

|

|

Comps |

79.27 |

86.16 |

96.15 |

|

|

|

|

Comp9 |

78.53 |

88.66 |

84.08 |

|

|

|

|

Comp 10 |

72.49 |

83.1 |

97.22 |

82.36 |

|

|

|

Comp 11 |

29.17 |

82.87 |

97.22 |

89.4 |

|

|

|

Comp 12 |

71.36 |

89.4 |

96 |

94.75 |

|

|

|

Comp13 |

64.89 |

94.75 |

97.86 |

|

|

|

|

Comp 14 |

36.17 |

79.51 |

87.71 |

|

|

|

|

Comp15 |

56.07 |

85.22 |

86.25 |

|

|

|

|

Comp 16 |

25.15 |

88.42 |

90.72 |

|

|

|

|

Comp17 |

71.24 |

93.51 |

90.69 |

|

|

|

|

Comp18 |

71.6 |

74.74 |

96.7 |

|

|

|

|

Comp19 |

55.26 |

95.94 |

98.24 |

|

|

|

|

Dup#1 |

|

95.59 |

95.76 |

92.74 |

86.74 |

94.99 |

|

Dup#2 |

|

94.67 |

94.92 |

93.73 |

91.46 |

94.96 |

|

Col#1 |

|

71.98 |

|

|

|

|

|

Col#2 |

|

94.37 |

|

|

|

|

|

Col#3 |

|

96.92 |

|

|

|

|

|

Col#4 |

|

76.78 |

|

|

|

|

|

Col#5 |

|

86.81 |

|

|

|

|

|

*Average, |

|

|

|

|

|

|

|

1/2" vs. 200 mesh |

66.98 |

84.86 |

|

|

|

|

|

Avg without vs. with Grav |

|

85.84 |

92.53 |

|

|

|

|

Avg without vs. with CIL |

|

89.13 |

|

90.6 |

|

|

|

Avg with CIL w/wo Grav |

|

95.13 |

95.34 |

|

89.1 |

|

|

Average vs. elevated NaCN |

|

95.13 |

|

|

|

94.98 |

Table 6. Summary of Newmont’s Southeast Pediment

preliminary Bottle Roll Leach Test including gravity, CIL and

additional cyanide test work sourced from Newmont’s historical

files.

Silica Ridge - Newmont’s Historical Test

Results

Newmont’s test work for Silica Ridge was similar

to the test work conducted at Southeast Pediment with materials

tested for oxide, transitional and sulfide ores over a range of

depths and selected geology to determine the range of results.

Newmont’s tested material comprised 80% passing -200 mesh (0.074mm)

with 24 hour leach yielding an average of 82.5% extracted gold for

all materials analysed and maximum gold extracted 97.85%. The

higher-grade recovery for Silica Ridge was improved compared to

Southeast Pediment likely due to inclusion of lower grade material

in the Southeast Pediment test work, Newmont found the best

recoveries were achieved from the higher gold grade materials.

Newmont’s Historical Test

Results

Silica Ridge

- initial bottle

roll results24 hr Leach, 80%

passing 200 mesh

|

Hole# |

Intervals |

Ore Type |

Sample ID |

Expected Avg. Au opt |

Actual Avg. au opt |

80% 200# Grind/Leach |

NaCN, lb/t |

Lime, lb/t |

|

NSM-00042 |

123.3-133.8 |

Oxide |

Comp 1 |

8.019 |

0.218 |

93.54 |

1.15 |

1.24 |

|

NSM-00044 |

95.0-99.1, 121.6-127.6, 139.1-144.2 |

Oxide |

Comp2 |

0.423 |

0.334 |

95.33 |

0.97 |

1.63 |

|

NSM-00051 |

389.0-399.7 |

Oxide |

Comp3 |

0.524 |

0.566 |

90.18 |

0.76 |

1.09 |

|

NSM-00051 |

399.7-441.0 |

Oxide |

Comp4 |

0.049 |

0.057 |

77.81 |

1.14 |

0.98 |

|

NSM-00069 |

118.7-131.1 |

Oxide |

Comp5 |

1.217 |

1.049 |

97.85 |

0.64 |

1.25 |

|

NSM-00076 |

110.8-120.0 |

Oxide |

Comp6 |

0.081 |

0.052 |

94.5 |

0.8 |

1.14 |

|

NSM-00102 |

41.9-68.0 |

Oxide |

Comp7 |

0.01 |

0.009 |

78.51 |

0.55 |

0.9 |

|

NSM-00102 |

68.0-95.8 |

Oxide |

Camp8 |

0.036 |

0.047 |

88.5 |

1.08 |

1.36 |

|

NSM-00102 |

95.8-135.5 |

Oxide |

Comp9 |

0.008 |

0.01 |

27.37 |

1.05 |

0.98 |

|

NSM-00104 |

22.4-38.6 |

Oxide |

Comp 10 |

0.251 |

0.242 |

94.8 |

1.12 |

0.86 |

|

NSM-00105 |

0-26.2 |

Oxide |

Comp 11 |

0.06 |

0.066 |

93.32 |

0.81 |

1.34 |

|

NSM-00105 |

50.2-81.5 |

Oxide |

Comp 12 |

0.008 |

0.008 |

69.24 |

0.84 |

0.77 |

|

NSM-00106 |

73.0-100.6 |

Oxide |

Comp 13 |

0.009 |

0.011 |

80.55 |

1.15 |

0.58 |

|

NSM-00106 |

116.2-153.0 |

Oxide |

Comp 14 |

0.212 |

0.265 |

97.15 |

0.85 |

1.74 |

|

NSM-00106 |

153.0-183.0 |

Oxide |

Comp 15 |

0.012 |

0.019 |

79.27 |

1.19 |

0.48 |

|

NSM-00111 |

141.0-143.0, 145.4-161.0 |

Oxide |

Comp16 |

0.01 |

0.01 |

68.49 |

1.01 |

1.54 |

|

NSM-00111 |

163.3-196.7 |

Oxide |

Comp 17 |

0.013 |

0.012 |

74.69 |

0.78 |

1.04 |

|

NSM-00111 |

201.7-290.0 |

Oxide |

Comp 18 |

0.015 |

0.Q16 |

70.2 |

0.76 |

1.62 |

|

NSM-00111 |

290.0-339.7, 343.7-351.9 |

Oxide |

Comp 19 |

0.013 |

0.011 |

79.12 |

1.24 |

1.61 |

|

NSM-00111 |

351.9-366.0 |

Oxide |

Comp 20 |

0.039 |

0.043 |

89.98 |

1.5 |

0.99 |

|

NSM-00111 |

366.0-384.8 |

Oxide |

Comp 21 |

|

0.026 |

52.46 |

1.58 |

1.47 |

|

NSM-00111 |

384.8-391.8, 393.5-405.6, 409.0-412.4 |

Oxide |

Comp 22 |

|

0.01 |

69.96 |

1.57 |

0.88 |

|

NSM-00112 |

6.0-22.4 |

Oxide |

Comp23 |

|

0.014 |

92.42 |

1.16 |

0.82 |

|

NSM-00112 |

124.9-217.7 |

Oxide |

Comp 24 |

|

0.011 |

74.03 |

1.51 |

1.28 |

|

NSM-00105 |

0·26.2 |

Oxide |

Column 5 |

|

0.072 |

95 |

0.5 |

1.68 |

|

NSM-00123 |

29.3-161.1 |

|

|

|

|

|

|

|

|

NSM-00123 |

12.5·183.5 |

|

|

|

|

|

|

|

|

NSM-00136 |

40.9·49.1 |

|

|

|

|

|

|

|

|

NSM-00102 |

41.9-135.5 |

Oxide |

Column 6 |

|

0.018 |

95.7 |

0.49 |

1.13 |

|

NSM-00106 |

153-183 |

|

|

|

|

|

|

|

|

NSM-111 |

141-161 |

Oxide |

Column 7 |

|

0.018 |

89.1 |

0.96 |

1.57 |

|

NSM-111 |

201.7-384.4 |

|

|

|

|

|

|

|

|

NSM-112 |

6-22.4 |

|

|

|

|

|

|

|

|

NSM-117 |

25-33.2 |

|

|

|

|

|

|

|

|

NSM-117 |

48-55.5 |

|

|

|

|

|

|

|

|

NSM-105 |

50.2-81.5 |

Oxide |

Column8 |

|

0.013 |

85.2 |

0.64 |

1.76 |

|

NSM-111 |

161-196.7 |

|

|

|

|

|

|

|

|

NSM-111 |

384.8-416 |

|

|

|

|

|

|

|

|

NSM-106 |

73-100.6 |

Oxide |

Column 9 |

|

0.012 |

98 |

0.8 |

1.85 |

|

NSM-112 |

194.5-217.7 |

|

|

|

|

|

|

|

|

Average |

0.112 |

82.49 |

0.99 |

1.23 |

Cyanide and Lime consumptions were 0.99 lb/st

and 1.23 lb/st, respectively.

Table 7. Summary of Newmont’s Silica Ridge

preliminary Bottle Roll Leach Test sourced from Newmont’s

historical files.

Further test work conducted by Newmont at Silica

Ridge suggests gravity concentration provides an improvement to the

extracted gold from 80.4% without gravity concentration to 85.5%

with gravity concentration.

Newmont’s Historical Test

Results

Silica Ridge

- initial bottle

roll results

|

Comp |

1.5inch Crush/Leach |

80% 200# Grind/Leach |

80% 200# Grind/Grav/ Leach |

|

1 |

43.22 |

93.54 |

95.14 |

|

2 |

14.47 |

95.33 |

96.7 |

|

3 |

12.77 |

90.18 |

97.65 |

|

4 |

13.91 |

77.81 |

92.87 |

|

5 |

3.72 |

97.85 |

99.67 |

|

6 |

78.12 |

94.5 |

96.34 |

|

7 |

51.09 |

78.51 |

91.24 |

|

8 |

62.87 |

88.5 |

91.93 |

|

9 |

71.3 |

27.37 |

62.51 |

|

10 |

72.22 |

94.8 |

95.11 |

|

11 |

45.67 |

93.32 |

95.58 |

|

12 |

60.1 |

69.24 |

83.5 |

|

13 |

77.72 |

80.55 |

89.76 |

|

14 |

56.03 |

97.15 |

98.4 |

|

15 |

60.55 |

79.27 |

93.9 |

|

16 |

54.83 |

68.49 |

79.54 |

|

17 |

66.24 |

74.69 |

79.68 |

|

18 |

55.69 |

70.2 |

48.95 |

|

19 |

70.59 |

79.12 |

88.93 |

|

20 |

83.72 |

89.98 |

85.18 |

|

21 |

40.95 |

52.46 |

69.06 |

|

22 |

74.5 |

69.96 |

61.98 |

|

23 |

80.47 |

92.42 |

92.68 |

|

24 |

58.72 |

74.03 |

54.99 |

|

Average |

54.56 |

80.39 |

85.05 |

Table 8. Summary of Newmont’s Silica Ridge preliminary Bottle

Roll Leach Test including grinding, gravity and leach test work

sourced from Newmont’s historical files.

North Hill, Silica Ridge and Southeast Pediment –

Kennecott’s Historical Test Results

Kennecott contracted McClelland Laboratories

Inc. to conduct agitated Leach Bottle Roll Test work on four drill

sample composites of reverse circulation drill-hole samples from

Silica Ridge and North Hill. The results yielded 80% and 82.5%

extracted gold from two drill holes SM-1 and SM-2 at North Hill.

For Silica Ridge the results yielded 80.9% and 54.9% extracted

gold. For Southeast Pediment the results yielded 84.3% and 82.8%

extracted gold. The results were conducted in 1987 for North Hill

and Silica Ridge and materials comprised 2kg split composites of

-1/4 inch (0.635cm) size which were bottled rolled for 96 hours.

The results for Southeast pediment were conducted in 1989 and

sourced from two drill holes SM-134 and SM-135 comprising 3kg split

samples.

Kennecott’s historical results are summarised in the table

below.

Kennecott’s Historical Test

Results

North Hill, Silica Ridge and Southeast

Pediment

|

Test Date |

Deposit |

Composite |

Head Assay* |

Calculated Head Assay |

Extraction (%) |

|

Hole ID |

Interval |

oz Au/ton |

oz Ag/ton |

oz Au/ton |

oz Ag/ton |

Au |

Ag |

|

1987 |

North Hill |

SM-1 |

|

0.034 |

0.21 |

0.035 |

0.07 |

80.0 |

28.6 |

|

SM-2 |

|

0.072 |

0.41 |

0.08 |

0.1 |

82.5 |

40.0 |

|

Silica Ridge |

SN012 |

|

0.166 |

0.81 |

0.178 |

0.94 |

80.9 |

26.6 |

|

SM-15 |

|

0.085 |

1.3 |

0.082 |

1.11 |

54.9 |

5.4 |

|

1989 |

Southeast Pediment |

SM-134 |

75-135ft |

0.071 |

0.57 |

0.07 |

0.52 |

84.3 |

15.4 |

|

SM-135 |

120-135ft |

5.128 |

2.9 |

3.477 |

2.24 |

82.8 |

61.2 |

| |

|

|

|

| * Conventional

fire assay fusion: assayed in triplicate (McClelland 1987;

1989) |

|

|

|

Table 9. Bottle Roll Agitated Leach Test work by

McClelland laboratory for Kennecott in 1987 and 1989.

KCA completed bottle roll, column leach and

gravity test work on surface and trench samples from Southeast

Pediment and Silica Ridge in 1996 and 1997. Summaries of these

results are provided below.

Southeast Pediment Test results

|

Date |

Test |

Composite |

Depth ft |

Type |

Head Assay (oz Au/ton) |

Size |

Time (days) |

Au Extraction% |

|

Average |

Calculated |

|

1996 |

Bottle Roll |

SEP-96-7 |

95-105 |

RC chips |

0.059 |

0.090 |

100# |

3 |

98.9 |

|

Bottle Roll |

SEP-96-7 |

95-105 |

RC chips |

0.059 |

0.074 |

As rec'd |

6 |

85.1 |

|

Bottle Roll |

SEP-96-10 |

50-60 |

RC chips |

5.192 |

5.098 |

100# |

3 |

99.7 |

|

SEP-96-42 |

90-100 |

|

Bottle Roll |

SEP-96-10 |

50-60 |

RC chips |

5.192 |

8.349 |

As rec'd |

6 |

27.4 |

|

SEP-96-42 |

90-100 |

|

Bottle Roll |

SEP-96-21 |

80-85 |

RC chips |

0.728 |

0.700 |

100# |

3 |

99.6 |

|

SEP-96-40 |

55-60 |

|

Bottle Roll |

SEP-96-21 |

80-85 |

RC chips |

0.728 |

0.688 |

As rec'd |

6 |

78.6 |

|

SEP-96-40 |

55-60 |

|

Bottle Roll |

SEP-96-23 |

80-85 |

RC chips |

0.025 |

0.023 |

100# |

3 |

91.3 |

|

Bottle Roll |

SEP-96-23 |

80-85 |

RC chips |

0.025 |

0.021 |

As rec'd |

6 |

95.2 |

|

Bottle Roll |

SEP-96-42 |

135-155 |

RC chips |

0.04 |

0.028 |

100# |

3 |

96.4 |

|

Bottle Roll |

SEP-96-42 |

135-155 |

RC chips |

0.04 |

0.033 |

As rec'd |

6 |

84.8 |

|

Bottle Roll |

SEP-96-55 |

190-195 |

RC chips |

0.022 |

0.027 |

100# |

3 |

96.3 |

|

Bottle Roll |

SEP-96-55 |

190-195 |

RC chips |

0.022 |

0.024 |

As rec'd |

6 |

91.7 |

|

1997 |

Bottle Roll |

SEP T-4 |

20-25 |

Trench |

0.017 |

0.02 |

100# |

2 |

85.0 |

|

Bottle Roll |

SEP T-4 |

75-80 |

Trench |

0.052 |

0.059 |

100# |

2 |

84.7 |

|

Bottle Roll |

SEP T-4 |

75-80 |

Trench |

0.052 |

0.058 |

1 inch |

8 |

72.4 |

|

Bottle Roll |

SEP T-5 |

34-40 |

Trench |

0.017 |

0.018 |

100# |

2 |

88.9 |

|

Bottle Roll |

SEP T-5 |

55-60 |

Trench |

0.029 |

0.031 |

100# |

2 |

93.5 |

|

Bottle Roll |

SEP T-6 |

75-80 |

Trench |

0.028 |

0.036 |

100# |

2 |

97.2 |

|

Bottle Roll |

SEP T-6 |

75-80 |

Trench |

0.58 |

0.606 |

1 inch |

8 |

76.2 |

|

Bottle Roll |

Bulk composite |

|

Trench |

0.171 |

- |

100# |

6 |

98.9 |

|

Column |

Bulk composite |

|

Trench |

0.171 |

0.160 |

0.25 inch |

111 |

92.5 |

|

Column |

Bulk composite |

|

Trench |

0.171 |

0.159 |

0.5 inch |

111 |

89.9 |

|

Column |

Bulk composite |

|

Trench |

0.171 |

0.164 |

1 inch |

111 |

87.8 |

|

Gravity Table |

SEP T-4 |

75-80 |

Trench |

0.036 |

|

28# |

|

14.2 |

|

Gravity Table |

SEP-96-51 |

85-90 |

RC chips |

1.642 |

|

28# |

|

37.3 |

|

Gravity Table |

SEP T-6 |

75-80 |

Trench |

0.559 |

|

28# |

|

38.9 |

Table 10. Southeast pediment Bottle Roll Test

work completed by KCA laboratory in 1986 and 1997. Materials were

sourced from reverse circulation drill chips and surface trench

samples.

Methodology for the above KCA analysis conducted

for the Southeast Pediment deposit is summarised below.

- 1996 Bottle Roll Leach tests on 6

composite samples of reverse circulation cuttings were tested with

500g splits of composite material pulverized to -100# and 1kg

splits at the as-received size which was 0.25 inch diameter.

- 1997 Bottle Roll Leach tests on 4

composite samples of surface trench and bulk composites for T-4 and

T-6 trenches with 500g splits pulverized to -100# and 10kg splits

crushed to -1 inch.

- 1997 Column leach tests were

conducted for 111 days on 40kg bulk composite samples with feed

size of -0.25 inch, -0.5 inch and -1 inch. Three of the trench

composites were crushed to -28# and passed through a Wifley No. 13

Table or Knelson Bowl Concentrator.

KCA testing of Silica Ridge Samples

|

Date |

Test |

Composite |

Type |

Head Assay (oz Au/ton) |

Size |

Time (days) |

Au Extraction % |

|

Average* |

Calculated |

|

1997 |

Bottle Roll |

T-8 Met 1&2 |

Trench |

0.058 |

0.06 |

100# |

2 |

95.0 |

|

Bottle Roll |

T-8 Met 1&2 |

Trench |

0.058 |

0.063 |

0.25 inch |

7 |

68.3 |

|

Bottle Roll |

T-8 Met 1&2 |

Trench |

0.058 |

0.072 |

1 inch |

7 |

56.9 |

|

1997b |

Bottle Roll |

Composite |

RC chips |

0.041 |

0.05 |

As rec'd |

8 |

70.0 |

|

Bottle Roll |

T-4 (310-320ft) |

Trench |

0.056 |

0.064 |

1 inch |

8 |

51.6 |

|

1997 |

Column |

T-8 Met 1&2 |

Trench |

0.058 |

0.072 |

0.25 inch |

85 |

86.1 |

|

Column |

T-8 Met 1&2 |

Trench |

0.058 |

0.065 |

0.5 inch |

85 |

78.5 |

|

Column |

T-8 Met 1&2 |

Trench |

0.058 |

0.074 |

1 inch |

85 |

77.0 |

| * Average of two

30g gire assays by two independent commercial laboratories (KCA

1997a: 1997b) |

Table 11. Silica Ridge Bottle Roll Test work by

KCA laboratory in 1997. Materials were sourced mostly from surface

trench samples and a single sample from reverse circulation drill

chips.

Methodology for the above KCA analysis conducted for the Silica

Ridge deposit is summarised below.

- 1997 Bottle

Roll Leach tests were conducted on two trench composite and one

reverse circulation sample. The T-8 trench composite was tested at

-100#, -0.25 inch and -1 inch with sample splits of 500g, 10kg and

10kg respectively. The T-4 trench composite comprised a 10kg split

and was tested at -1inch for 96 hours. The reverse circulation

sample of 10kg split was leached for 96 hours at the as-received

size. The T-8 trench composite was tested in column leaches for

-0.25 inch, -0.5 inch and -1 inch feed sizes. A total of 1.73 to

1.79 lbs/ton cyanide was consumed, and 2.28 lbs/ton lime was added

to the three columns.

Historical Bulk Sampling from Southeast

Pediment

In 2002 eight trenches and a test pit were dug

comprising 1,067t of high-grade mineralisation which was processed

at the Newmont Twin Creeks Juniper mill. The bulk sample had a

calculated grade of 0.224 ounce per ton and 0.913 ounce per ton of

silver and recovery of the gold was reported as 95.2% and silver

79.5%.

Western States Minerals Corporation also sent a

bulk sample from Southeast Pediment to Gekko Systems for gravity

concentration testing which achieved 27.5% gold and 24% silver.

Intense cyanidation of the gravity concentrate extracted >97%

gold in the concentrate in 12 hours and >99% gold in the

concentrate in 24 hours.

Further study is required to incorporate a

gravity concentration circuit in conjunction with a cyanide

leaching over longer timeframes.

About Sandman

In December 2020, Gold Bull purchased the

Sandman Project from Newmont. Gold mineralization was first

discovered at Sandman in 1987 by Kennecott and the project has been

intermittently explored since then. There are four known pit

constrained gold resources located within the Sandman Project,

consisting of 21.8Mt @ 0.7g/t gold for 494,000 ounces of gold;

comprising of an Indicated Resource of 18,550kt @ 0.73g/t gold for

433kozs of gold plus an Inferred Resource of 3,246kt @ 0.58g/t gold

for 61kozs of gold. Several of the resources remain open in

multiple directions and the bulk of the historical drilling has

been conducted to a depth of less than 100m. Sandman is

conveniently located circa 25-30 km northwest of the mining town of

Winnemucca, Nevada.

Qualified Person

Cherie Leeden, B.Sc Applied Geology (Honours),

MAIG, a “Qualified Person” as defined by National Instrument

43-101, has read and approved all technical and scientific

information contained in this news release. Ms. Leeden is the

Company’s Chief Executive Officer. Cherie Leeden relied on resource

information contained within the Technical Report on the Sandman

Gold Project, prepared by Steven Olsen, a Qualified Person under NI

43-101, who is a Qualified Persons as defined by the National

Instrument NI 43-101. Mr. Olsen is an independent consultant and

has no affiliations with Gold Bull except that of an independent

consultant/client relationship. Mr. Olsen is a member of the

Australian Institute of Geoscientists (AIG) and is the Qualified

Person under NI 43-101, Standards of Disclosure for Mineral

Projects.

About Gold Bull Resources Corp.

Gold Bull’s mission is to grow into a US focused

mid-tier gold development Company via rapidly discovering and

acquiring additional ounces. The company’s exploration hub is based

in Nevada, USA, a top-tier mineral district that contains

significant historical production, existing mining infrastructure

and an established mining culture. Gold Bull is led by a Board and

Management team with a track record of exploration and acquisition

success.

Gold Bull’s core asset is the Sandman Project,

located in Nevada which has a 494,000 oz gold

resource as per 2021 43-101 Resource Estimate. Sandman is located

23 km south of the Sleeper Mine and boasts excellent large-scale

exploration potential.

Gold Bull is driven by its core values and

purpose which includes a commitment to safety, communication &

transparency, environmental responsibility, community, and

integrity.

Cherie LeedenPresident and CEO, Gold Bull Resources Corp.

For further information regarding Gold Bull

Resources Corp., please visit our website at www.goldbull.ca or

email admin@goldbull.ca.

Cautionary Note Regarding Forward-Looking

StatementsNeither the TSX Venture Exchange nor its

Regulation Services Provider (as that term is defined in the

policies of the TSX Venture Exchange) accepts responsibility for

the adequacy or accuracy of this release.

This news release contains certain statements

that may be deemed “forward-looking statements” with respect to the

Company within the meaning of applicable securities laws.

Forward-looking statements are statements that are not historical

facts and are generally, but not always, identified by the words

“expects”, “plans”, “anticipates”, “believes”, “intends”,

“estimates”, “projects”, “potential”, “indicates”, “opportunity”,

“possible” and similar expressions, or that events or conditions

“will”, “would”, “may”, “could” or “should” occur. Although Gold

Bull believes the expectations expressed in such forward-looking

statements are based on reasonable assumptions, such statements are

not guarantees of future performance, are subject to risks and

uncertainties, and actual results or realities may differ

materially from those in the forward-looking statements. Such

material risks and uncertainties include, but are not limited to,

the Company’s ability to raise sufficient capital to fund its

obligations under its property agreements going forward, to

maintain its mineral tenures and concessions in good standing, to

explore and develop its projects, to repay its debt and for general

working capital purposes; changes in economic conditions or

financial markets; the inherent hazards associates with mineral

exploration and mining operations, future prices of copper and

other metals, changes in general economic conditions, accuracy of

mineral resource and reserve estimates, the potential for new

discoveries, the ability of the Company to obtain the necessary

permits and consents required to explore, drill and develop the

projects and if obtained, to obtain such permits and consents in a

timely fashion relative to the Company’s plans and business

objectives for the projects; the general ability of the Company to

monetize its mineral resources; and changes in environmental and

other laws or regulations that could have an impact on the

Company’s operations, compliance with environmental laws and

regulations, dependence on key management personnel and general

competition in the mining industry. Forward-looking statements are

based on the reasonable beliefs, estimates and opinions of the

Company’s management on the date the statements are made. Except as

required by law, the Company undertakes no obligation to update

these forward-looking statements in the event that management’s

beliefs, estimates or opinions, or other factors, should

change.

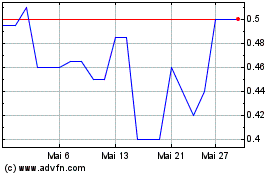

Gold Bull Resources (TSXV:GBRC)

Historical Stock Chart

Von Nov 2024 bis Dez 2024

Gold Bull Resources (TSXV:GBRC)

Historical Stock Chart

Von Dez 2023 bis Dez 2024