IPG Photonics Launches Cobot Laser Welding and Cleaning System

08 Mai 2024 - 3:00PM

IPG Photonics Corporation (NASDAQ: IPGP), the world leader in

fiber laser solutions, today announced the launch of an automated

cobot laser welding and cleaning system for fabrication and

manufacturing industries.

Turnkey Laser Automation Made

EasyThe new cobot is a fully automated, laser welding and

cleaning system which can be configured with any existing and

future LightWELD® welding laser source. It expands

IPG Photonics’ industry leading LightWELD family of portable laser

welders. Cobots, also called collaborative robots, are industrial

robots which work with humans often for tasks that require

precision, repeatable results or to streamline repetitive tasks.

IPG Photonics’ cobot laser production system makes automating

welding jobs easy for fabricators regardless of experience with

cobots or laser processing. Designed and delivered as a turnkey

laser system, welders and shop owners benefit from simple

installation and setup, to enable production in as little as just

one day.

All-in-One Cobot Laser Welding &

Cleaning SystemThe LightWELD Cobot System is comprised of

an industrial base with the LightWELD laser source, system

controls, a 1 x 1.5 m work surface, drag-and-drop operator user

interface, and long-reaching cobot arm which holds the LightWELD

gun. As with standalone LightWELD products, the system is also

capable of switching between laser welding and laser cleaning in

just seconds by simply changing the nozzle with no tools required.

The system is also fully compatible with the LightWELD wire feeder,

which further expands the system capability.

Effortless Part

ProgrammingRegardless of prior cobot experience, welders

are able to teach the cobot with manual guidance in just minutes

and control all system functionality from a single graphical user

interface which requires no coding knowledge. Cobot motion and

LightWELD parameters are easily accessed, as are the built-in

editable presets for optimized welding and cleaning. The welder can

test and simulate the programmed processing ahead of beginning a

job, which ensures results are as expected. This significantly

reduces scrap and the need for rework due to the precision and

consistency of the cobot motion system and reliability of the

LightWELD laser source.

Safety Configurations to Match Any

EnvironmentIPG Photonics puts safety first in every

product they produce and is committed to educating the industry on

how laser safety standards for welding differ only slightly from

the required protection and procedures in traditional welding,

which makes adoption of laser-based solutions simpler and faster.

The LightWELD Cobot System is available in three configurations:

the base system that is integrated into a dedicated and enclosed

shop space; an integrated system with a removable safety enclosure

with dual-channel interlocking doors and laser-safe window; and in

a LightWELD Studio comprised of modular laser-safe panels with

sliding door, laser-safe window and safety signage.

Empowering Skilled Welders and Enabling

New CapabilitiesBy automating repetitive laser welds for

the LightWELD Cobot System, skilled welders can focus on more

demanding tasks and pursue new skills enabling themselves and shop

owners to increase productivity and expand capabilities. These

benefits, plus lessening the need to grind and rework parts that

typically result from hand welding inconsistencies, reduce overall

operating expenses and accelerate return on investment.

“This turnkey automated laser welding and

cleaning system provides the shortest path for fabricators to

install and easy to use system and produce consistent results

efficiently and safely,” said Daniel Earley, LightWELD Product

Manager. “My firsthand experience using the system validates that

anyone with or without prior welding or cobot skills can quickly

learn to program and control the entire system in a matter of

minutes. We are excited to bring this system to market as it will

enable the fabrication industry to increase productivity with

automated processing, address the shortage of qualified welders,

and facilitate new shop capabilities.”

The LightWELD Cobot System offers the

flexibility and range of motion to tackle multiple project setups

with mixes of parts, joint configurations and material

combinations, both on the system work surface and on adjacent work

surfaces. The small footprint of the system and integrated leveling

caster wheels enable easy system repositioning into other areas of

the shop floor.

The combination of welders and cobots lower the

cost-per-part by reducing downtime, rework and scrap, while

increasing production capacity, processing consistency and overall

quality for fabrication shops of all sizes.

About IPG Photonics

IPG Photonics Corporation is the leader in

high-power fiber lasers and amplifiers used primarily in materials

processing and other diverse applications. The company’s mission is

to make its fiber laser technology the tool of choice in mass

production. IPG accomplishes this mission by delivering superior

performance, reliability and usability at a lower total cost of

ownership compared with other types of lasers and non-laser tools,

allowing end users to increase productivity and decrease costs. IPG

is headquartered in Marlborough, Massachusetts and has more than 30

facilities worldwide.

For more information, visit

www.LightWELD.com

Investor Contact

Eugene Fedotoff

Senior Director, Investor Relations

IPG Photonics Corporation

508-597-4713

efedotoff@ipgphotonics.com

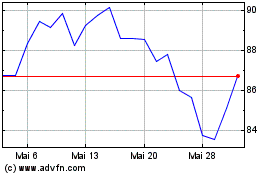

IPG Photonics (NASDAQ:IPGP)

Historical Stock Chart

Von Okt 2024 bis Nov 2024

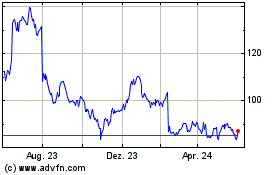

IPG Photonics (NASDAQ:IPGP)

Historical Stock Chart

Von Nov 2023 bis Nov 2024