ArcelorMittal S.A.: ArcelorMittal inaugurates flagship carbon

capture and utilisation project at its steel plant in Ghent,

Belgium

- €200 million

CCU plant first of its kind in the

European steel industry

- Project part of

multi-technology strategy to reduce

carbon emissions at Ghent

plant

8 December

2022,

11:00 CET

At an event held at its steel plant in Ghent, Belgium today,

attended by the Prime Minister of Belgium, Alexander De Croo,

Flemish Minister-President Jan Jambon, members of the Belgian and

Flemish governments, European Investment Bank Vice-President Kris

Peeters, ArcelorMittal Executive Chairman, Lakshmi Mittal, and

ArcelorMittal Europe CEO, Geert Van Poelvoorde, ArcelorMittal (‘the

Company’) successfully inaugurated its flagship carbon capture and

utilisation (‘CCU’) project.

The €200 million ‘Steelanol’ project is a first of its kind for

the European steel industry. Utilising cutting edge carbon

recycling technology developed by our project partner LanzaTech,

the CCU plant uses biocatalysts to transform carbon-rich waste

gases from the steelmaking process and from waste biomass into

advanced ethanol, which can then be used as a building block to

produce a variety of chemical products including transport fuels,

paints, plastics, clothing and even cosmetic perfume, hence helping

to support the decarbonisation efforts of the chemical sector. The

advanced ethanol will be jointly marketed by ArcelorMittal and

LanzaTech under the Carbalyst® brand name.

Once production reaches full capacity the

Steelanol plant will produce 80 million litres of advanced ethanol,

almost half of the total current advanced ethanol demand for fuel

mixing in Belgium. It will reduce annual carbon emissions from the

Ghent plant by 125,000 tonnes. Other partners involved in the

Steelanol project are Primetals Technologies and E4tech.

ArcelorMittal Ghent will soon inaugurate another first for the

European steel industry, with its ‘Torero’ project set to come on

stream in the first quarter of 2023. The €35 million Torero project

is designed to process sustainable biomass (initially in the form

of waste wood that cannot be used in other applications) for use as

a raw material input into the blast furnace, hence lowering the

volume of fossil coal used. This project will reduce annual carbon

emissions in Ghent by 112,500 tonnes. ArcelorMittal Ghent intends

to add a second reactor to its Torero project over the next two

years, hence doubling the size of the project.

Speaking at the event,

Alexander De Croo, Prime

Minister of Belgium,

said:

"I am pleased to see ArcelorMittal is taking bold and innovative

steps by decarbonising its steel production at its new installation

in Ghent. This is an important step in the fight against climate

change while safeguarding our future competitiveness and securing

Belgian jobs. By investing in clean energy technologies,

ArcelorMittal is not only helping to lower carbon emissions, but it

is also setting the standard for the industry. The only way forward

is cleaner production that leads to better products."

Jan Jambon, Flemish

Minister-President

and Minister of Foreign Affairs,

Culture, Digitalisation and

Facility Management, said:

“Maintaining and enhancing heavy industry in Europe is of

crucial importance for economic growth and strategic autonomy. The

high ambitions of ArcelorMittal for sustainability and circularity

fit within the climate targets of the Flemish government: a carbon

neutral and circular society by 2050, while safeguarding industrial

and economic activities in our region.”

Lakshmi Mittal, ArcelorMittal Executive

Chairman, said:

“ArcelorMittal Ghent is widely regarded as one of the finest

steel plants in Europe, staffed by talented, committed and

forward-thinking people. We intend to ensure that reputation

endures into the future and I believe the work being undertaken

here lays the ground for what the steel plant of the future will

look like. This is a steel plant which is embracing the latest

innovative technologies; which is using sources of circular carbon;

which captures and re-uses as many of its waste products as

possible, recycling them into something of value; and which is

preparing for a future when green hydrogen will remove the need to

use any fossil carbon. It is a strong example of what is possible

with energy, effort and of course, brilliant scientific minds. It

also demonstrates what can be achieved through partnership, so I

must thank the Belgian and Flemish governments and the EIB for the

support they are providing towards our efforts to transition to

net-zero steelmaking.”

ArcelorMittal CEO Aditya

Mittal

added:

“The imperative to accelerate the road to net zero has never

been greater. Given the scale of the challenge, it’s important to

be open to all technology solutions and certainly, at ArcelorMittal

we are open to all technologies that can take steelmaking to near

zero. The investments we are planning here at Ghent are a great

testament to that. It’s also become abundantly clear that

collaboration and partnership is essential to deliver the

systems-wide change we need to reach zero, as this project

demonstrates. We have worked closely together with a wide group of

stakeholders here in Belgium and indeed also more broadly across

Europe, on the conditions and infrastructure that support the

investment in these types of technologies and the transition to net

zero. I want to thank everyone who has supported our efforts and

made today – the inauguration of the European steel industry’s

first carbon capture and utilisation plant – possible.”

ArcelorMittal Europe CEO, Geert Van Poelvoorde,

said:

“Inaugurating the European steel industry’s first carbon capture

and utilisation plant is an important moment for our European

business, and for our target to reduce the carbon intensity of the

steel we produce in Europe by 35 per cent by 2030. We have long

held the view that multiple technologies will be required for our

industry to reach net zero, and today is an important proof point

of our commitment to developing and deploying those technologies as

quickly as possible, and to making meaningful progress this decade.

Our ambition is clear, to lead our industry’s efforts to reach net

zero. It is a huge challenge, but also a tremendous opportunity. A

low-carbon European economy needs low-carbon emissions steel to

build its renewable energy infrastructure, low-carbon buildings and

electric vehicles. And our customers expect us to deliver

low-emissions steel today. Projects such as Steelanol and Torero

will help us to meet that demand through our suite of XCarb®

products.”

ArcelorMittal Belgium CEO, Manfred Van

Vlierberghe, said:

“ArcelorMittal Belgium has a passion for sustainability and

circularity. We are heading to become the sustainable steel company

of the future through new breakthrough technologies such as

Steelanol. This technology contributes to strengthening our global

leadership in terms of CO2 and energy efficiency in the steel

sector. Steelanol is a strong asset towards our Europe-wide goal of

reducing CO2 emissions by 35 per cent by 2030, and of achieving

carbon-neutral steelmaking by 2050.”

Jennifer Holmgren, CEO

LanzaTech,

said:

“The leadership and commitment of governments and large

companies like ArcelorMittal is needed to ensure single use carbon

becomes a thing of the past. This significant milestone brings us

closer to creating a circular carbon economy at a time when all

sustainable solutions are required to solve our climate

crisis.”

The projects being undertaken in Ghent form an important part of

ArcelorMittal’s 2030 climate action roadmap, in which the Company

is targeting reducing the carbon intensity of the steel it produces

by 25 per cent globally, and by 35 per cent across its European

operations. In addition to the many decarbonisation technologies

ArcelorMittal is developing and deploying, the Company is also

investing in the best and brightest technologies which hold rich

potential to accelerate the decarbonisation of steelmaking through

its XCarb® Innovation Fund. To date, ArcelorMittal has committed to

investments totalling $222.5 million, including an investment of

$30 million in LanzaTech, the Company’s partner in the Steelanol

project. To learn more about the Company’s climate action efforts

visit https://corporate.arcelormittal.com/climate-action.

Additional quotes

Vincent Van Peteghem,

Deputy Prime Minister of the Belgian Government

and Minister of Finance, said:

“Today, we must have the courage to make clear choices for our

economy of tomorrow. And Steelanol is a fine example of that. It

makes me proud to see this sample of top innovation developed in

our country and in Ghent. I am convinced that this European first

will not only strengthen the reputation of the Ghent port area but

will also be an inspiration far beyond our national borders.

Inspiration to arrive at innovative investments that can offer a

solution to the climate problem through thorough cooperation. This

is how we build tomorrow together.”

Tinne Van der

Straeten, Belgian Minister of Energy,

said:

“ArcelorMittal's climate investment is a tangible example of how

circular industry is becoming a reality. Gas from blast furnaces is

converted into the sustainable fuel bioethanol. A waste product

thus becomes a raw material for industry and biofuel for heavy

transport. By greening the production process, we anchor industry

and jobs domestically, reduce our dependence on fossil fuels and

cut CO2 emissions.”

Jo Brouns, Flemish

Minister of Economy, Innovation, Work, Social Economy and

Agriculture, said:

“Innovation is the engine of progress, and I am proud to see

that ArcelorMittal Ghent took those words to heart. They rose to

the challenge and made remarkable progress on the road to our goals

of carbon neutrality with this new breakthrough, Steelanol. Taking

on the challenge to implement biotechnology on such a grand scale,

ArcelorMittal Ghent has rightly earned their place as one of the

biggest innovators in steel production.”

Matthias Diependaele,

Flemish Minister of Finance and Budget, Housing and Immovable

Heritage said:

“Flanders is taking the lead in keeping strategic industries in

Europe, this is important to make our industry and the whole

economy resilient against external events and calamities.

Furthermore, the Steelanol projects secures jobs in the port of

Ghent, providing an income to thousands of households in the region

and career possibilities to white and blue collar employees.”

Lydia Peeters, Flemish

Minister of Mobility and Public Works, said:

"It's great to see a company like ArcelorMittal taking up the

gauntlet to do even more work on the transition to greater

sustainability. Through innovation and technology, we can

significantly reduce emissions, which is good for the climate. The

opening of the Steelanol plant is a great example of how

cooperation between ports, universities and private partners can

lead to innovative and state-of-the-art results. ArcelorMittal

provides a lot of jobs in the port of Ghent. From my powers I am

working on improving road and water access in and around the Ghent

canal zone, just think of the R4WO project where we are tackling

the road and bicycle infrastructure. At the same time, we are

betting on the future with the continued construction of the new

lock in Terneuzen. The lock should provide better access and

smoother flow of the increasing shipping traffic."

Kris Peeters,

Vice-President European Investment Bank, said: “The

European Investment Bank is very glad to support ArcelorMittal,

which is of major economic importance for local communities in

Belgium, in its drive to really cut its emissions. Steel is used

all around us and plays a key role in our economies, meaning that

making the production process greener is of vital importance for

both our climate and local employment. As the climate bank of

Europe, we know how important this project is for ArcelorMittal but

also for the steel sector as a whole. Saving energy and switching

to renewables cannot achieve our climate goals by themselves,

innovation will be key.”

Carina Van

Cauter, Governor East-Flanders,

said:

“North Sea Port district is a frontrunner in sustainability,

with companies and governments working together across borders.

ArcelorMittal is a crucial partner and catalyst within the Canal

Zone to achieve a sustainable basic industry. As a government, we

need to provide an enabling regulatory framework. Sustainable

growth at the border, no limits to growth."

Mathias De Clercq,

Mayor City of Ghent, said:

“Ghent is fast becoming a continental hub for clean tech

innovation. We want to make Ghent and our port a worldwide

forerunner in terms of the circular economy and ArcelorMittal plays

a very important role in this. We must see our industry as a part

of the solution, not as a problem. Together we can reduce carbon

emissions and work towards a climate neutral society.”

Dr. Alexander

Fleischanderl, Head of Green

Steel, Primetals Technologies,

said:

“The steel sector’s goal to achieve net-zero by 2050 definitely

requires breakthrough CCU technologies. The Steelanol project is an

incredible showcase for carbon recycling in Europe, ready to be

rolled out in heavy industry. We are extremely excited having been

a strong partner since the very first days and proud of being a

shareholder in LanzaTech.”

Dr. Ausilio Bauen, ERM

Partner, said:

“Since 2015, E4tech, an ERM Group company, has been proudly

supporting the Steelanol Consortium in evaluating how the concept

of flue gas recycling could improve the greenhouse gas footprint of

steel production by creating a petrol substitute from recycled

carbon. E4tech remains committed to supporting sustainable

innovations in the industrial and energy sectors and to promoting a

circular economy. It has been an inspiring journey to work

alongside forward-thinking companies like ArcelorMittal, LanzaTech

and Primetals and we hope the Steelanol Ghent plant will pave the

way for further decarbonisation of the steel and energy

sectors.”

ENDS

Steelanol project

partners

LanzaTech is the global leader in gas

fermentation technology. The company provides novel and economic

routes to ethanol, jet fuel and high-value chemicals from gas

streams.

Primetals Technologies,

Limited, headquartered in London, United Kingdom, is a

pioneer and world leader in the fields of engineering, plant

building, and the provision of lifecycle services for the metals

industry.

E4tech is an international strategic

consultancy focused on sustainable energy. Since 1997 they have

worked with companies, governments, and investors to help them

understand the global opportunities and challenges of clean

energy.

About ArcelorMittal

ArcelorMittal is the world's leading steel

company, with a presence in 60 countries and primary steelmaking

facilities in 16 countries. In 2021, ArcelorMittal had revenues of

$76.6 billion and crude steel production of 69.1 million metric

tonnes, while iron ore production reached 50.9 million metric

tonnes.

Our purpose is to produce ever smarter steels

that have a positive benefit for people and planet. Steels made

using innovative processes which use less energy, emit

significantly less carbon and reduce costs. Steels that are

cleaner, stronger and reusable. Steels for electric vehicles and

renewable energy infrastructure that will support societies as they

transform through this century. With steel at our core, our

inventive people and an entrepreneurial culture at heart, we will

support the world in making that change. This is what we believe it

takes to be the steel company of the future.

ArcelorMittal is listed on the stock exchanges

of New York (MT), Amsterdam (MT), Paris (MT), Luxembourg (MT) and

on the Spanish stock exchanges of Barcelona, Bilbao, Madrid and

Valencia (MTS).

For more information about ArcelorMittal please

visit: http://corporate.arcelormittal.com/

| |

|

| Contact

information ArcelorMittal Investor Relations |

|

| |

|

| General |

+44 20 7543

1128 |

| Retail |

+44 20 3214

2893 |

| SRI |

+44 20 3214

2801 |

|

Bonds/CreditE-mail |

+33 171 921

026investor.relations@arcelormittal.com |

|

|

|

|

|

|

| Contact

information ArcelorMittal Corporate Communications |

|

| Paul

WeighTel:E-mail: |

+44

20 3214 2419press@arcelormittal.com |

|

ArcelorMittal Belgium

Communications |

|

|

Jan CornelisTel:E-mail |

+32 499 599 394jan.cornelis@arcelormittal.com |

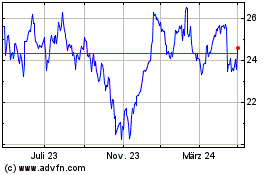

ArcelorMittal (EU:MT)

Historical Stock Chart

Von Mär 2024 bis Apr 2024

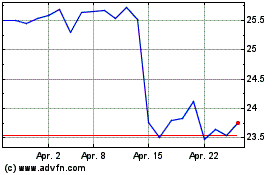

ArcelorMittal (EU:MT)

Historical Stock Chart

Von Apr 2023 bis Apr 2024